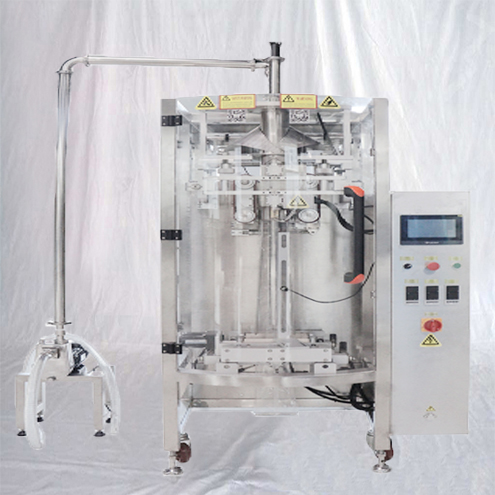

Paraffin wax packing machine with heating &mixing pumping system liquid bags packaging equipment VFF

Automatic liquid packaging equipment for Paraffin Wax with heating and mixing &pumping system

This wax packing machine is widely used in food, medicine, daily consumable, pesticide and some other special industry, with air remove device which can remove 98% air through packing,special used in paraffin wax,tomato paste,ice bag package.

Features of liquid packaging equipment:

1.SS304 of machine frame and material contact part, PLC control, touch screen panel.

2.Remove 98% air throught packing, which make the package save space and more beautiful.

3.Easy to operate and maintain.

4.Automatic measurement/filling/bag making/cutting/date print.

Machine parameters of liquid packing machine:

| Model Number | YX-PW420 |

| Measuring range | 200-2000ML |

| Film width | 120-420mm |

| Bag length | 80-300mm |

| Bag width | 50-200mm |

| Machine body | Stainless steel SUS304 |

| Sealing way | Back type sealing |

| speed | 20-60bags per minute |

| Air consumption | 0.8Mpa 0.3m3/min |

| Power supply | 3phase 4wire 3.5KW,50Hz |

| weight | 520kg |

Dimension |

L1330*W1140*H1800mm |

| Bags materials | PE POF Laminated film etc |

Application of packaging machine:

It is suitable for packing all kinds of liquid and paste,semi-liquid such as tomato paste,paraffin wax,salad dressing,lotion,etc.

Bag samples

Remove 98% air through packing,which is helpful for storage and transportation,as well as beautiful package.

whole machine(model YX-PW420 Packing VFFS equipment) pictures

Liquid Packaging Machine details

FAQ-Frequently Asked Questions

1. Q: How can I be sure to get assurance &what I purchased after payment?

A: In China, there is anti-money laundry policy, for which the government strictly manages every payment from abroad. The payment you made will firstly go to their managing account, and only when we submit bill of loading to them, payment will be released to us;

the payment will be returned to you or pended by State Administration of Foreign Exchange,SAFE. if we are not able to make shipment and submit bill of lading within lead time.

We,in addition,have exported different kinds of packaging machinery to more than 150 countries and are able to offer you the reference list among cooperating customers to verificate our business and company.

2. Q: How can I be sure the machine will absolutely work for my product?

A: We will test run the machine once the building completes for 10 minutes, with your sample product ( when sample product is a must) and send you test run video to prove the machine works well and stable, for your product, before balance payment and shipment.

3. Q: Will you send technical staff to help me with installation and operation training?

A: The machine will be packed with little disassembly in one plywood crate, so they will be plug and use type, no need special installation.

And we will also send you installation and operating tutorial videos before shipment.Remote assistance by video call or meeting is available as well.

In rare cases, we can send technical staff if desperately needed, but there is 150USD/day engineer salary and flight ticket, visa application, travelling, board and lodging shall be at buyer's account.

4. Q: How many years warranty and how do I do the machine repairing and maintenance?

A: One-year warranty from the date of shipment, during which if any parts fault, we will courier to your replacing parts with replacing instructions, all at our cost.

The replacing is simple and easy to be completed by anybody.

The machines are maintenance free types, some daily lubrication will prolong the service life though.

5. Q: When can i expect my email or questions to be replied?

A: Our working time is 9:00am--18:00pm Monday--Saturday, any email shall be replied within 24 hours normally.WhatsApp better if in urgence.

For an enquiry, the most recommended way of contact is by email, by sending your final product&photos to our emails above-mentioned, due to our possible time difference.

6.Q: How long can I receive machine if I place the order?

A:Machine building takes 3-60 work days depending on the degree if customization.

Tabletop small machines usually takes only 3-7 work days to build, and larger, more customized machines normally takes 20 work days.

Some very customized built machines that require designing from scratch ,may take 40 work days or even more.

Shipping time will be 3-40 days depending on the shipping service you choose( courier, air or ocean shipping) and the distance of the ship-to country from China.

7.Q: How to preceed the business to buy PENGLAI-Branded Machines?

A:Customer confirms to order--Supplier sends Proforma Invoice--Customer pays 50% prepayment by wire transfer&sends out samples to be test run on machine to be built--Supplier starts the designing of machine after confirming receival of payment and sample--starts raw material purchasing--

processing of parts--assembling parts--PLC programming&commisioning--machine test run with the samples and sends test run video to customer for approval--test run video approved--customer pays balance--supplier makes plywood crates and processes shipping--supplier sends the needed import customs clearance documents

--machine received and cusomer easily installs and operates the machine,with the tutorial video by supplier--Any issues with operation, customer sends video demo and supplier responds with tutorial video.

Annotations: what is the paraffin wax?

Paraffin wax (or petroleum wax) is a soft colorless solid derived from petroleum, coal or oil shale that consists of a mixture of hydrocarbon molecules containing between twenty and forty carbon atoms. It is solid at room temperature and begins to melt above approximately 37 °C (99 °F),and its boiling point is above 370 °C (698 °F).Common applications for paraffin wax include lubrication, electrical insulation, and candles;dyed paraffin wax can be made into crayons. It is distinct from kerosene and other petroleum products that are sometimes called paraffin.

Un-dyed, unscented paraffin candles are odorless and bluish-white. Paraffin wax was first created by Carl Reichenbach in Germany in 1830 and marked a major advancement in candlemaking technology, as it burned more cleanly and reliably than tallow candles and was cheaper to produce.

In chemistry, paraffin is used synonymously with alkane, indicating hydrocarbons with the general formula CnH2n+2. The name is derived from Latin parum ("very little") + affinis, meaning "lacking affinity" or "lacking reactivity", referring to paraffin's unreactive nature.

ALL RIGHTS RESERVED BY ®SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

Previous: liquid honey sauce doypack packing machine for pre made stand up bags bag-given packaging equipment

Next: Return

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved