USA Austin customer ordered&tested spout bags filling screw capping machine fully automatic with bag

Very nice to meet our USA customer Nipun and Jaya from Austin,who got our company Invitation letter and applied for visa, visited our factory in the last Week for spending two days

checking and testing run their ordered machinery model YX-50F spout bags filling capping machine automatic with bags loading syste.

Finally everything went very well and our customer soon afterwards paid us in our office the balance payment for processing the quick shipping

due to our chinese Traditional New Year .Good Luck! we finally catched up with the last shipping in 2014 for our customer .

As follow is the basic information for this sucessful international transaction

Down Payment for spout bags filling capping machine model YX-50F

Spout bags sent for our manufacturing for machine after down payment

Testing run of videos for spout bags filling screw capping machines model YX-50F

Final Wooden case packaging for Yogurt milk filling capping equipment for our USA customer before chinese New Year

Below is the Basic parameter of spout bags filling capping machine fully automatic with bags loading system

This spout bags filling capping machine model YX-50F series is full automatic production line with such processes: automatic pouch-loading, fixed-position filling, cleaning spout, cap feeding and inserting, pouch position testing, cap screwing (applying magnetic adjusting torque for rather stability), quality production output.

PLC control.

Note:

1. According to the customer request, provides the special design.

2. The machine disposition may make the choice.

Machines vary with the controlling system and different optional function :

►Model YX-50F series automatic spout stand up bags filling capping machine for juice liquid jelly milk production with PLC touch screen system

Filling capping with bags loading system&date coding function

Automatic bags loading system for feeding bags before filling

Date coding&ink solution parts for printing expiry date after filling capping bags

►machines with touch screen controlling system&automatic bags loading system for filling capping process

►The spout bags filling capping machine automatic model YX-50F series with CIP cleaning system

►Model YX-50F series automated spout bags caps filling sealing machine with CIP system&ink printer function:

Technical parameters of spout bags filling sealing machine automatic model YX-50F-04

|

Parameters |

Contents |

|

Nozzles Injector |

4 |

|

Packing Speed |

3800-4300 bags/Hour |

|

Volume |

50-500ml |

|

Powder |

1.6 kw |

|

Voltage |

380V/50HZ (three phase) |

|

Air Pressure |

0.5-0.7Mpa |

|

Air consumption |

0.5 m3/min |

|

Out dimension |

Main Machine: 2200*1430 * 2000mm Send bag holder: 2200*500*1500mm |

|

Weight |

1500kg |

The parameter above is only for reference, please make the object as the standard.

Basic Work flow:

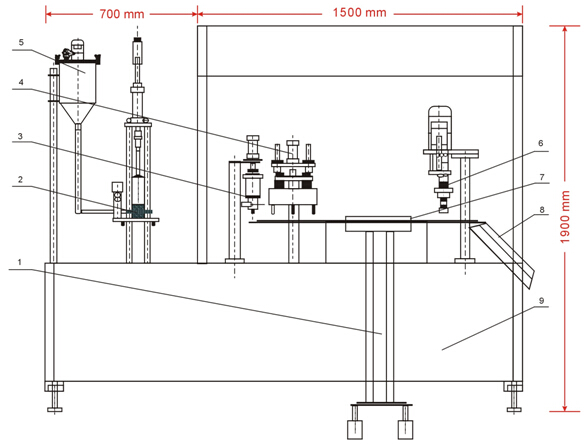

Structure of spout bags filling capping machine automatic model YX-50F series

|

1 |

electrical appliance case |

7 |

photoelectric checking device |

|

2 |

pouch carrier |

8 |

cap-screwing device |

|

3 |

filling device |

9 |

finished product exit |

|

4 |

charging basket |

10 |

turntable |

|

5 |

cleaning device |

11 |

structure |

|

6 |

cap sorter device |

|

|

|

1 |

pouch carrier |

6 |

cap-screwing device |

|

2 |

filling device |

7 |

turntable |

|

3 |

plunger case |

8 |

finished product exit |

|

4 |

cleaning device |

9 |

structure |

|

5 |

charging basket |

|

|

Details of spout bags filling sealing machine automatic model YX-50F series

Bags fed into the hanger

Vibrator for feeding caps after filling

Filling capping parts

Final products output along the guidar board

Spare parts for filling capping machine

Packing List together with the machines

|

Name |

Model |

quantity |

|

Filling Sealing Machine |

YX-50F |

1 |

|

Operation Instruction |

|

1 |

|

Manufacturer Certificate |

|

1 |

|

Hexagon ring spanner |

M4 |

1 |

|

Hexagon ring spanner |

M5 |

1 |

|

Hexagon ring spanner |

M6 |

1 |

|

Hexagon ring spanner |

M8 |

1 |

|

Hexagon ring spanner |

M10 |

1 |

|

The six angle wrench |

14—17mm |

1 |

|

The six angle wrench |

19—22mm |

1 |

|

The six angle wrench |

24—30mm |

1 |

|

Cross Screwdriver |

6 inches |

1 |

|

Straight Screwdriver |

6 inches |

1 |

|

Thermocouple |

K type 1.0m |

1 |

|

Electrical Heated Tube |

Ф12x70 220V 180W |

2 |

Wooden case packaging before ocean shipping for automatic stand up spout bags filling capping machine

Quality Assurance for filling capping machine fully automatic with bags loading system&date printer:

1. Each machine is manufactured by our professional workers.

2. Each machine with a strict inspection before out of storage.

3. Each machine use a large number of 304 stainless steel.

4. Each machine use good quality electric elements.

5. After-sales service commitment: after one month, 3 months... we will have return visiting by phone or mail.

6. The warranty time is one year.

7. Within Warranty period, if under the usage of instruction sheet, any product broken or damage, we will offer the repair service for free or replace for free, but clients pay for the freight from China to local place. If need our engineer go to help, clients pay for the freight of round-trip.

8. Beside the warranty days, we continue to provide life-long maintenance services.

PENGLAI INDUSTRIAL CORPORATION LIMITED

Previous: UAE customer orders another set of plane labeling machine semi automatic for plane surface perfume b

Next: Italian customers buy manual liquid filling machine liquid filler equipment macchina di rifornimento

Tel: +86-755—86718316 Fax: +86-755—25417648

Email: jackdu999@yahoo.com

Copyright @ 2003-2021 SHENZHEN PENGLAI Industrial Corporation Limited. All rights reserved